Research - Design of sustainable iron fuel

The urgent need to decarbonize the global energy sector has spurred the search for innovative solutions to replace fossil fuels with renewable energy sources, a critical step in combating climate change. However, the intermittent nature and uneven geographic distribution of renewable energy, such as solar and wind, pose significant challenges for energy storage and transportation. Among the emerging solutions, the concept of metal energy carriers has gained considerable attention as a promising approach to store and transport renewable energy efficiently. Iron, in particular, has emerged as a standout candidate due to its abundance, safety, ease of storage, and established global trade infrastructure.

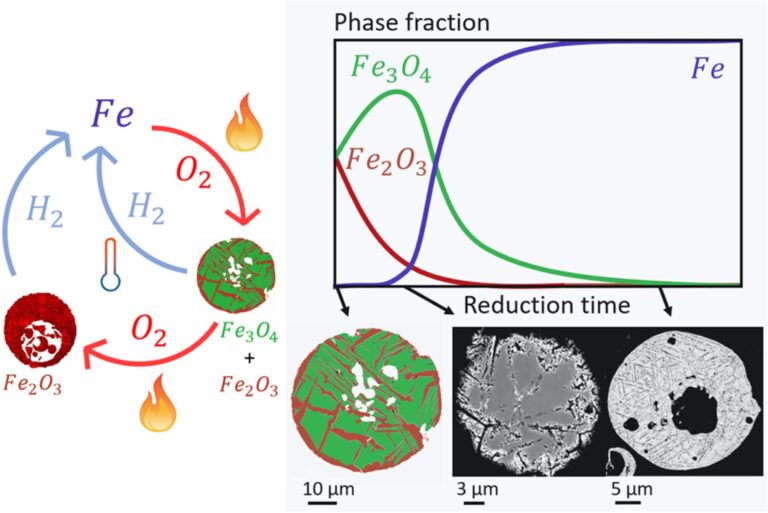

Iron powder can serve as a sustainable fuel, undergoing combustion to release energy while producing iron oxides as a by-product. These iron oxides can then be reduced back into iron powder using hydrogen-based direct reduction powered by renewable energy, creating a closed-loop, net CO₂-free energy cycle. This process, known as the iron fuel cycle, offers a compelling pathway to decarbonize energy-intensive sectors. However, to realize its full potential, a deeper understanding of the underlying materials science principles governing the combustion and reduction processes is essential.

Here, we aim to address this challenge by investigating the intricate relationship between alloying elements, microstructure evolution, chemical transformations, and reaction kinetics during the redox cycles of iron-based powders. By adopting a multiscale microstructure and chemical analysis approach, this research seeks to unravel the fundamental mechanisms that govern the performance of iron as a sustainable fuel. This knowledge will enable the development of advanced alloy design strategies tailored for sustainable metal fuels, enhancing their efficiency and scalability. Furthermore, the research has the potential to integrate waste materials, such as oxide scales, machinery chips from steel production lines, and mixed post-consumer scrap, into the iron fuel cycle, transforming them into valuable resources for renewable energy storage.

Related publications

- Phase transformations and microstructure evolution during combustion of iron powder, Acta Materialia, 239 (2022), 118261.

- Hydrogen-based direct reduction of combusted iron powder: Deep pre-oxidation, reduction kinetics and microstructural analysis, Acta Materialia, 268 (2024), 119752.