Research - Hydrogen-based ironmaking

The steel industry is a cornerstone of modern infrastructure and economic development, yet it is also one of the largest contributors to global carbon dioxide (CO₂) emissions, accounting for over 7-8% of the total worldwide emissions. This significant environmental impact stems primarily from the carbon-intensive processes used in conventional ironmaking, particularly blast furnaces that rely on coal and coke as reducing agents. As the world strives to meet ambitious climate targets and transition to a low-carbon economy, decarbonizing the steel industry has become a critical priority.

Hydrogen-based metallurgical methods have emerged as a promising pathway to achieve this goal. Among these, hydrogen-based direct reduction (HyDR) stands out as a transformative approach. In the HyDR process, hydrogen gas (H₂) is used as a clean reducing agent to convert iron ore into direct reduced iron (DRI) through a solid-gas reduction reaction, with water (H₂O) as the only by-product. This method eliminates the need for carbon-based reductants, thereby avoiding CO₂ emissions and offering a sustainable alternative to traditional ironmaking.

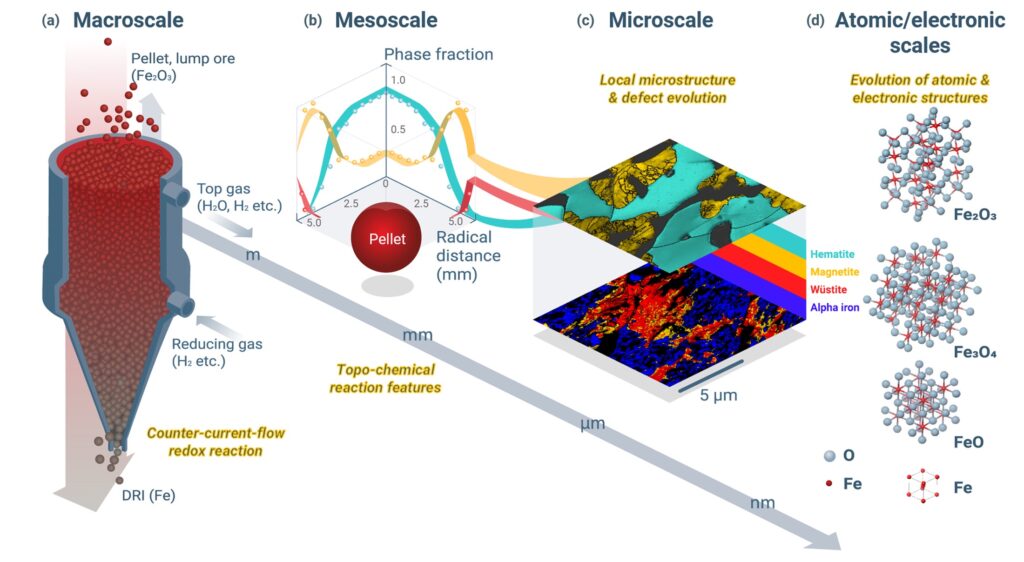

Despite its potential, the widespread adoption of HyDR requires a deeper understanding of the underlying chemical and physical phenomena governing the process. Factors such as reaction kinetics, heat and mass transfer, microstructure evolution, and the influence of raw material properties play critical roles in determining the efficiency and scalability of HyDR. To address these challenges, we employ a multiscale approach, integrating experimental, theoretical, and computational methods to unravel the complexities of the HyDR process.

The insights gained from this research will not only advance fundamental knowledge but also facilitate the design and optimization of raw materials and process parameters for HyDR. By bridging the gap between laboratory-scale experiments and industrial-scale applications, we also closely collaborate with our industrial partners to accelerate the transition to hydrogen-based ironmaking, contributing to the decarbonization of the steel industry and supporting global efforts to combat climate change. Through this teamwork, we envision a future where steel production is both sustainable and environmentally responsible, paving the way for a greener industrial ecosystem.

Related publications

- Hierarchical nature of hydrogen-based direct reduction of iron oxides, Scripta Materialia, 213 (2022), 114571.

- Reducing iron oxide with ammonia: A sustainable path to green steel, Advanced Science,16 (2023), 2300111.

- Green ironmaking at higher H2 pressure: Reduction kinetics and microstructure formation during hydrogen-based direct reduction of hematite pellets, Journal of Sustainable Metallurgy, 10 (2024), 1127-1140.

Elucidating the microstructure evolution during hydrogen-based direct reduction via a case study of single crystal hematite, Acta Materialia, 294 (2025), 121174.